MADE IN BANDON

122 years

Founded by our Farmers in 1903

480+

Employees in our Community

240+

Generational Farmer Suppliers

3

Retail Stores

Bandon Co-op has a very long and proud tradition in West Cork, whilst also playing a significant role both nationally and internationally. We are deeply committed to supporting our farming families, our employees and our customers, and strive to work together to achieve this.

Check out our

SALE

Household & Homewares

€34.99

Original price was: €34.99.

€29.99

Current price is: €29.99.

Add to cart

NINJA THIRSTI TRAVEL BOTTLE IN BLACK 530ML

Household & Homewares

€34.99

Original price was: €34.99.

€29.99

Current price is: €29.99.

Add to cart

NINJA THIRSTI TRAVEL BOTTLE IN GREY 530ML

Household & Homewares

€34.99

Original price was: €34.99.

€29.99

Current price is: €29.99.

Add to cart

NINJA THIRSTI TRAVEL BOTTLE IN MINT 530ML

Electrical

€329.99

Original price was: €329.99.

€219.99

Current price is: €219.99.

Add to cart

SHARK CORDLESS PET CLEANER IZ380UKT

Air Fryers

€349.99

Original price was: €349.99.

€289.98

Current price is: €289.98.

Add to cart

NINJA ARTISAN OUTDOOR PIZZA/AIRFRYER MO201UK

Electrical

€239.99

Original price was: €239.99.

€209.99

Current price is: €209.99.

Add to cart

NINJA ICE CREAM NC300UK

Electrical

€939.99

Original price was: €939.99.

€649.99

Current price is: €649.99.

Add to cart

SHARK POWER DETECT NEVER TOUCH PRO 2 IN 1 WHITE RV2800ZEUKWH

Air Fryers

€239.98

Original price was: €239.98.

€179.99

Current price is: €179.99.

Add to cart

NINJA 7.6L FOODI DUAL ZONE AIR FRYER AF300UK

Bulbs

€11.99

Original price was: €11.99.

€8.04

Current price is: €8.04.

View Product

YELLOW DAFFODIL BULBS 3KG

Electrical

€139.99

Original price was: €139.99.

€119.99

Current price is: €119.99.

Add to cart

NINJA 2-IN-1 FOODI POWER NUTRI BLENDER CB100UK

Electrical

€239.99

Original price was: €239.99.

€179.99

Current price is: €179.99.

Add to cart

NINJA 3-IN-1 FOOD PROCCESSOR WITH AUTO-IQ BN800UK

Electrical

€209.99

Original price was: €209.99.

€139.99

Current price is: €139.99.

View Product

NINJA FOODI STAYSHARP KNIFE BLOCK K32005UK

Accessories

€54.95

Original price was: €54.95.

€49.46

Current price is: €49.46.

View product

AGRISHIELD WATERPROOF BREATHABLE JACKET

Garden Tools

€39.95

Original price was: €39.95.

€35.95

Current price is: €35.95.

View product

MANURE 4 FORK PROMG – F105DLH LS S

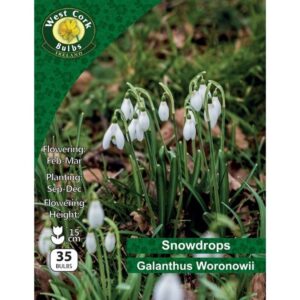

Gardening & Outdoors

€11.99

Original price was: €11.99.

€8.04

Current price is: €8.04.

Add to cart

Snowdrops Galanthus woronowii 35 bulbs pack 5/6

Cookers

€269.99

Original price was: €269.99.

€239.99

Current price is: €239.99.

Add to cart

NINJA DOUBLE STACK 2 DRAWER AIR FRYER 7.6L SL300UK

Camping Accessories

€289.99

Original price was: €289.99.

€209.99

Current price is: €209.99.

View product

NINJA FROSTVAULT HARD COOLER WITH DRY VAULT FB131UKWH

BBQ & Barbecue Accessories

€479.99

Original price was: €479.99.

€350.00

Current price is: €350.00.

View product

NINJA WOODFIRE ELECTRIC BBQ GRILL & SMOKER OG851UK

BBQ & Barbecue Accessories

€529.99

Original price was: €529.99.

€410.00

Current price is: €410.00.

View product

NINJA WOODFIRE ELECTRIC BBQ GRILL & SMOKER OG901UK

Electrical

€529.99

Original price was: €529.99.

€350.00

Current price is: €350.00.

Add to cart

SHARK CORDLESS DETECT VACUUM WITH AUTO EMPTY SYSTEM

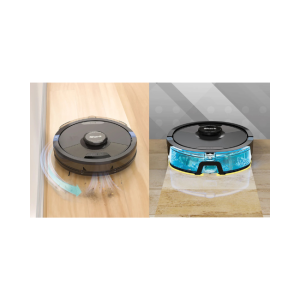

Electrical

€469.99

Original price was: €469.99.

€289.98

Current price is: €289.98.

View Product

SHARK ROBOT CLEANER RV2620WDUK

Electrical

€209.99

Original price was: €209.99.

€149.99

Current price is: €149.99.

Add to cart

SHARK STAINSTRIKER MAX PX200UKT

Electrical

€129.99

Original price was: €129.99.

€87.95

Current price is: €87.95.

Add to cart

SONY BLACK NOISE CANCEL HEADPHONE WHCH720NBCE7

Electrical

€129.99

Original price was: €129.99.

€87.95

Current price is: €87.95.

Add to cart

SONY WHITE NOISE CANCEL HEADPHONE WHCH720NWCE7

Audio

€59.99

Original price was: €59.99.

€39.95

Current price is: €39.95.

Add to cart

SONY WIRELESS BLUETOOTH HEADPHONES WHITE WH-CH520

Accessories

€33.95

Original price was: €33.95.

€30.55

Current price is: €30.55.

View product

AGRISHIELD WATERPROOF BREATHABLE TROUSER

practical tips for your home and garden

Visit our

RETAIL CENTRES

Proud to be

ASSOCIATED WITH